Unlimited Resources Corporation recently completed the installation of a Model M-80 Granutech/Saturn Grizzly and Screening system into a plant for the production of decorative mulch.

In this particular application we were contacted by one of our previous customers who had purchased a whole tire down to 2” tire chips (TDF) package of equipment from us at an earlier time. They were faced with only being able to sell their tire chips or TDF for fuel for a local cement kiln or for daily cover at a local landfill and neither of these were very profitable. So after doing a great deal of studying what to do to enhance their profitability they finally contacted our company to see what we could help them do to reduce the size of their tire chips to make them easier to market.

Our company generally has a large inventory of used refurbished Recycling Equipment on hand at all times. In this particular instance we were able to offer them a complete package of equipment that would take these 2” tire chips and process them on down in size ambiently to three different size classifications ¾”- ½” mulch, ½” – ¼”mulch, and finally ¼” minus size crumb rubber. In doing this we used many of the items that we already had in inventory here at Unlimited Resources Corporation. We also purchased many of the items such as screw auger conveyors and drum magnets brand new from outside vendors. Our goal was to give them the best possible option to help them meet their goals and at the cheapest possible price. In so doing we were also stepping outside the box and trying to make the product as wire free and fluff free as possible.

Ultimately we furnished them with the following system that works just great for their particular application.

Equipment List

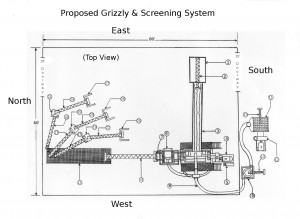

Proposed Grizzly and Screening System

1. Custom built surge/storage bin (7’ wide x 10’ long)

2. Custom built 12” diameter x 12’ long screw auger conveyor

3. Custom built 36” wide x 30’ long Grizzly in-feed conveyor

4. Model 80 Granutech/Saturn Grizzly 300 h.p.

5. Electrical control panel (Grizzly and screen system)

6. Self-cleaning cross belt magnet

7. Vibratory conveyor

8. Custom built ductwork (For Grizzly aspiration system)

9. Cyclone and airlock with custom built stand

10. Custom built 12” diameter x 12’ long screw auger conveyor

11. Dust collector

12. Dust collector blower

13. Custom built 12” diameter x 12’ long screw auger conveyor

14. Custom built 24” diameter x 20’ long screw auger conveyor

15. Rotex 6’ wide x 26’ long 2 deck screener

16. Custom built 12” diameter x 16’ long screw auger conveyor

17. Custom built 12” diameter x 16’ long screw auger conveyor

18. Custom built 12” diameter x 16’ long screw auger conveyor

19. Drum magnet with custom built stand

20. Drum magnet with custom built stand

21. Drum magnet with custom built stand

22. Custom built 12” diameter x 12’ long screw auger conveyor

23. Custom built 12” diameter x 12’ long screw auger conveyor

24. Custom built 12” diameter x 12’ long screw auger conveyor

25. Custom built “Super Sack” manual bagging station

26. Custom built “Super Sack” manual bagging station

27. Custom built “Super Sack” manual bagging station

We found this system was producing around 20% of the material in the ¾” – ½” mulch size, and around 50% of the material was in the ½” – ¼” mulch size, and the remaining 30% of the material was in the ¼” minus size. We had used ¾” size opening screens in the Grizzly and it worked very well in the production of this mulch which was then painted and sold for decorative mulch. They chose to build their own paint and drying system but we could have also done this part of the project if they had wanted us to. If they were to add another small screen such as a Rotex or a Swepco they could screen the ¼” minus size material and actually make some sellable crumb rubber.

If you’re looking into the possibility of taking your current 2” tire chips down in size then this might be an alternative for you to look at when the time comes. Just remember to call Unlimited Resources Corporation and ask for one of our experienced sales staff to assist you with your next Tire Recycling Equipment purchase. Our “can do crew” will be glad to quote any project you might have from Primary shredding of scrap tires all the way down to the production of 30-40 mesh crumb rubber. We take pride in providing our customers refurbished recycling equipment that stands the test of time.