Unlimited Resources Corporation (URC) currently has a complete whole semi-truck or passenger tire down to ¾” minus rubber shredding or processing system for sale at a very attractive price. This Granutech/Saturn waste tire recycling system is basically the same as new. This system offers without a doubt one of the best buys in the marketplace today. This tire shredding system comes with all the equipment needed to make it a complete system. You won’t find a better system available in the industry today and you definitely won’t find one at this tremendous price. We ask you to take the time to check into this offering because we only have one of these systems that we have built over this past Fall &Winter at this SPECIAL price. Check this system out before it’s too late!!

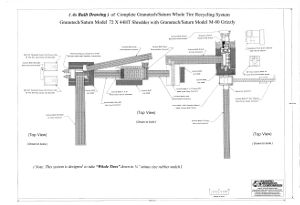

Complete Granutech/ Saturn Whole Waste Tire Recycling System

This system takes “Whole Tires” down to 3/4″ minus size rubber

1. Custom built whole tire in-feed conveyor (new) 48” wide X 38’ long flat slider belt with sides

2. Custom built in-feed hopper for shredder (new) for doing a split chamber shredder design

3. Completely Refurbished Granutech/Saturn Model 72 X 44HT shredder with dual high out-put SAI hydraulic motors (Note: these hydraulic motors can operate @ 5,000 PSI). Shredder will be furnished with 1.8”wide X 2 hook knives in the primary shredding part of the cutting chamber and 1-1/2” X 12 hook knives in the secondary shredding part of the cutting chamber This shredder will have considerably more torque than your normal 72 X 44HT and would work well for the shredding of semi-truck tires and super single truck & trailer tires.

4. (2)-200 H.P. Hydraulic Power Pac’s (Refurbished). Each unit has (1) 200 H.P. Electric motor driving a Rex Roth 5,000 PSI Hydraulic Pump (These hydraulic power pac’s are what power the SAI hydraulic motors on the 72 X 44HT shredder) These will make this shredder a real work horse compared to a normal 72 X 44HT shredder.

5. Custom built Shredder Electrical Control Panel

6. Custom built stand (new) for shredder with catwalks(new)

7. Custom built shredder out-feed conveyor (new) 36” wide X 24’ long troughed slider belt

8. Custom built 5’ X 12’ Rotary disc screen classifier (new) with 10 H.P. electric motor set up to produce a 2” nominal chip.

9. Custom built stand (new) for classifier with catwalks (new)

10. Custom built Short recirculating conveyor (new) 28” wide X 8’ long troughed slider belt

11. Custom built Long recirculating conveyor (new) 30” wide X 35’ long troughed slider belt

12. Custom built 2” Sized material out-feed conveyor (new) 30” wide X 26’ long troughed slider belt

13. Refurbished Custom Built 7’ X 11’ Surge Bin with 10 H.P. drag chain conveyor

14. Custom built in-feed conveyor for M-80 Grizzly (Refurbished) 40” wide X 32’ long troughed slider belt/ with sides

15. Completely Refurbished Granutech/Saturn Model M-80 Grizzly with 300 H.P. electric motor

16. Factory built Grizzly stand with (new) custom built catwalks

17. Refurbished vibratory dis-charge conveyor

18. Cross-belt self-cleaning magnet (new)

19. Custom built stand for magnet (new)

20. Custom built sized material out-feed conveyor (new)30” wide X 40’ long

21. Custom built stainless steel auger for wire removal (refurbished) 14” dia. X 24’ long

22. Aspiration system (used like new) Donaldson/Torit Model #DF02-16 Cartridge Style Filters Dust Collector with 40 H.P. Air Pro Blower

23. Cyclone/ with refurbished Airlock and (new) Custom Built Stand

24. Custom built Grizzly Electrical Control Panel

This is a very heavy-duty built system in all aspects, built to stand the test of time. Of course the front half of this system, the shredder and disc screen classifier, is very capable of processing in the range of 8-10 tons per hour of 2” nominal chips. The back half of the system with the Grizzly would be limited to only 4-5 tons of ¾”minus chips being able to be processed. This system will come complete with all the legs, hoppers, and electrical controls needed to complete the system. This system offers one of the most attractive prices available and all the above work has been performed by our experienced service technicians in our shop and much of this system is NEW. This system is still currently set up in our shop for you to inspect if you so desired. As part of the price we will include sending two of our service technicians to assist with installation of this system at your location in the continental USA. CALL Elaine or Richard @660-295-4204 for more information pertaining to this unique onetime offer! We have many pictures of this system as well as a detailed drawing available upon request! We are in the final phases of completing this system and only have the electrical wiring left to complete this entire system. We have samples of the rubber that was produced by a system identical to this. If you would like to have a sample we will be glad to get one sent out to you ASAP. This system would work ideally for producing rubber mulch if you added a screen and a few more screw auger conveyors and some drum magnets to the system. And of course we could also furnish you with a paint system also if you needed to paint this mulch to make it more marketable. This rubber mulch would then be a product that would add a considerable amount to your bottom line as far as profitability.

Whole above system priced at ONLY $795,000.00

When in doubt always give the “can do crew” at URC a call for all your waste tire recycling equipment needs. And don’t hesitate to give us a call for any and all types of other recycling equipment you might have a need for. We value our customers and treat all of them the way we would want to be treated if it was us doing the buying. Call URC, the ones who have been serving this industry now for over twenty years. See attached drawing of this system for more details and please don’t hesitate to call if you have any questions.